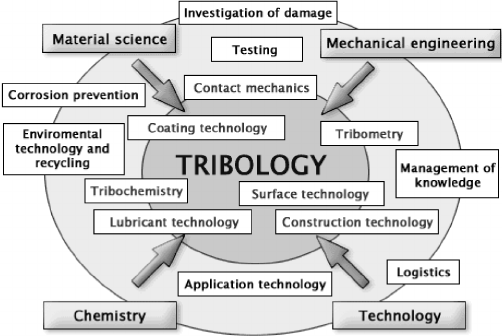

Tribology, the science and technology of interacting surfaces in relative motion, is a cornerstone of mechanical engineering. It encompasses the study of friction, wear, and lubrication, three critical phenomena that significantly impact the performance and longevity of mechanical systems.

Key Concepts in Tribology

- Friction: The resistance to relative motion between two contacting surfaces.

- Wear: The loss of material from a surface due to mechanical action.

- Lubrication: The introduction of a substance between two contacting surfaces to reduce friction and wear.

Importance of Tribology in Mechanical Engineering

- Energy Efficiency: Reducing friction through effective lubrication and design can significantly improve energy efficiency, leading to lower operating costs and reduced environmental impact.

- Component Longevity: Proper tribological design and maintenance can extend the lifespan of mechanical components, reducing the need for frequent repairs and replacements.

- Reliability: Tribological failures can lead to unexpected equipment downtime and costly repairs. Understanding and addressing tribological issues is essential for ensuring the reliability of mechanical systems.

- Noise Reduction: Friction can generate noise and vibration. By minimizing friction, engineers can improve the noise performance of mechanical equipment.

Applications of Tribology

- Bearing Design: Tribology plays a crucial role in designing bearings, which are essential components in many mechanical systems. By understanding friction and wear, engineers can optimize bearing design for efficiency, durability, and noise reduction.

- Lubricant Formulation: Developing effective lubricants is another important aspect of tribology. Lubricants can be liquid, solid, or gaseous, and their formulation depends on the specific application and operating conditions.

- Surface Coatings: Applying special coatings to surfaces can significantly reduce friction and wear. These coatings can be made from various materials, including polymers, ceramics, and composites.

- Manufacturing Processes: Tribological principles are also applied in manufacturing processes, such as metal cutting, forming, and grinding, to improve efficiency and tool life.

Challenges and Future Directions

Despite significant advancements in tribology, there are still many challenges to overcome, including:

- Complex Tribological Systems: Many real-world tribological systems involve multiple components and operating conditions, making it difficult to accurately model and predict their behavior.

- Extreme Environments: Some applications, such as aerospace and automotive, involve extreme temperatures, pressures, and loads, which can make it challenging to develop suitable lubricants and coatings.

- Biotribology: The study of friction and wear in biological systems, such as joints and tissues, is a relatively new field with many unanswered questions.

As research in tribology continues to progress, we can expect to see even more innovative solutions to reduce friction and wear in mechanical systems. These advancements will not only improve the efficiency and reliability of machinery but also contribute to a more sustainable future.