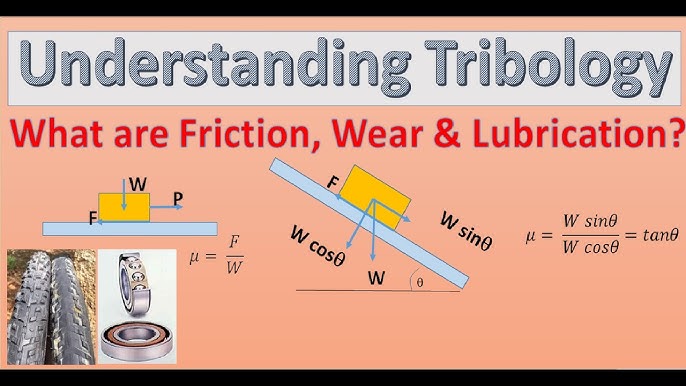

Tribology, the study of friction, wear, and lubrication, is a fundamental aspect of many everyday activities and industries. Here are some common examples of tribology in action:

Transportation

- Automotive: The engine, transmission, and brakes of a car rely heavily on tribology. Engine oils reduce friction between moving parts, brake pads and rotors reduce friction to slow the vehicle, and transmission lubricants ensure smooth gear shifting.

- Railways: Train wheels and tracks are designed to minimize friction, allowing for efficient and smooth travel. Lubricants are used to reduce wear and improve the performance of railway components.

Manufacturing

- Machining: Cutting tools, such as drills and milling cutters, rely on tribology to efficiently remove material. Coolants are used to reduce friction and heat, preventing tool wear and improving the quality of the finished product.

- Metal Forming: Processes like forging and stamping involve significant friction between the workpiece and the tooling. Lubricants are used to reduce friction and prevent sticking, ensuring the desired shape and quality of the finished product.

Consumer Products

- Zippers: The smooth operation of a zipper depends on the friction between the teeth and the slider. Lubricants can be used to reduce friction and prevent jamming.

- Door Hinges: Door hinges rely on tribology to ensure smooth and quiet operation. Lubricants are used to reduce friction and prevent squeaking.

Sports and Recreation

- Skating: The low friction between ice and skate blades allows for smooth and efficient gliding.

- Cycling: Bicycle chains and bearings require regular lubrication to reduce friction and prevent wear, ensuring smooth and efficient pedaling.

These are just a few examples of how tribology plays a crucial role in our daily lives. By understanding and controlling friction, wear, and lubrication, engineers and designers can improve the efficiency, reliability, and longevity of mechanical systems.

Tribology, the study of friction, wear, and lubrication, is a fundamental aspect of many everyday activities and industries. Here are some common examples of tribology in action:

Transportation

- Automotive: The engine, transmission, and brakes of a car rely heavily on tribology. Engine oils reduce friction between moving parts, brake pads and rotors reduce friction to slow the vehicle, and transmission lubricants ensure smooth gear shifting.

- Railways: Train wheels and tracks are designed to minimize friction, allowing for efficient and smooth travel. Lubricants are used to reduce wear and improve the performance of railway components.

Manufacturing

- Machining: Cutting tools, such as drills and milling cutters, rely on tribology to efficiently remove material. Coolants are used to reduce friction and heat, preventing tool wear and improving the quality of the finished product.

- Metal Forming: Processes like forging and stamping involve significant friction between the workpiece and the tooling. Lubricants are used to reduce friction and prevent sticking, ensuring the desired shape and quality of the finished product.

Consumer Products

- Zippers: The smooth operation of a zipper depends on the friction between the teeth and the slider. Lubricants can be used to reduce friction and prevent jamming.

- Door Hinges: Door hinges rely on tribology to ensure smooth and quiet operation. Lubricants are used to reduce friction and prevent squeaking.

Sports and Recreation

- Skating: The low friction between ice and skate blades allows for smooth and efficient gliding.

- Cycling: Bicycle chains and bearings require regular lubrication to reduce friction and prevent wear, ensuring smooth and efficient pedaling.

These are just a few examples of how tribology plays a crucial role in our daily lives. By understanding and controlling friction, wear, and lubrication, engineers and designers can improve the efficiency, reliability, and longevity of mechanical systems.