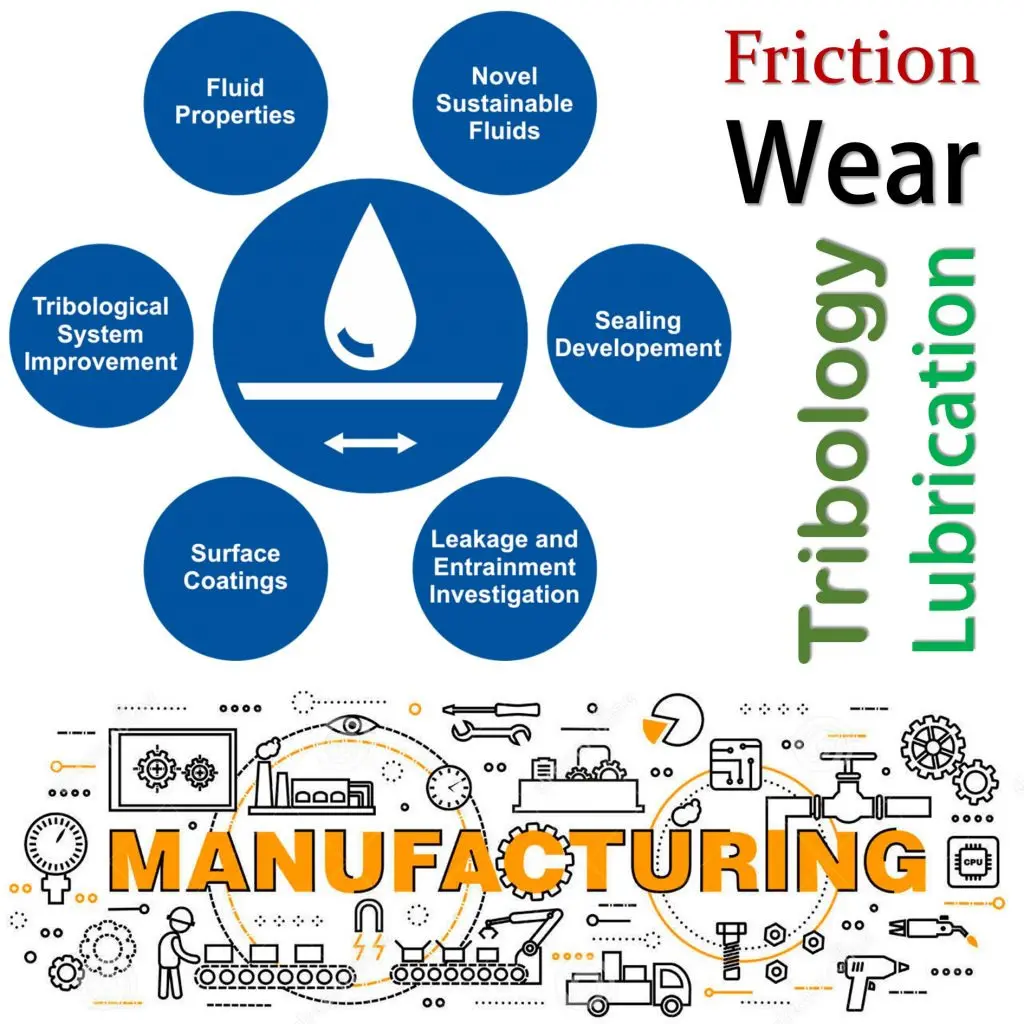

Tribology, the study of friction, wear, and lubrication, is a critical field within mechanical engineering that has a profound impact on industrial efficiency and productivity. By understanding and controlling these phenomena, engineers can optimize the performance and lifespan of machinery, reduce energy consumption, and minimize downtime.

Key Applications of Tribology in Industry

- Manufacturing: Tribology is essential in various manufacturing processes, including:

- Machining: Cutting tools, such as drills and milling cutters, rely on tribology to efficiently remove material. Coolants are used to reduce friction and heat, preventing tool wear and improving the quality of the finished product.

- Metal Forming: Processes like forging and stamping involve significant friction between the workpiece and the tooling. Lubricants are used to reduce friction and prevent sticking, ensuring the desired shape and quality of the finished product.

- Assembly: Tribological considerations are essential in designing and assembling machinery to minimize friction and wear, ensuring smooth operation and reducing maintenance costs.

- Transportation: Tribology plays a crucial role in the transportation industry:

- Automotive: Engine oils, transmission lubricants, and brake systems rely on tribological principles to reduce friction and wear, improve fuel efficiency, and ensure safe operation.

- Railways: Train wheels and tracks are designed to minimize friction, allowing for efficient and smooth travel. Lubricants are used to reduce wear and improve the performance of railway components.

- Aerospace: Tribology is critical for the design and maintenance of aircraft components, ensuring safety and reliability.

- Energy Generation and Transmission: Tribology is essential in:

- Power Plants: Bearings, seals, and other components in power plants rely on tribological principles to reduce friction and wear, improving efficiency and reducing downtime.

- Transmission Systems: Lubricants are used to reduce friction and wear in transmission systems, ensuring efficient energy transfer.

- Consumer Products: Tribology is also relevant in the design and manufacturing of consumer products:

- Electronics: Bearings and other moving components in electronics require effective lubrication to reduce friction and ensure reliable operation.

- Household Appliances: Washing machines, refrigerators, and other appliances rely on tribological principles for efficient and reliable operation.

Benefits of Tribology in Industry

- Increased Efficiency: By reducing friction and wear, tribology can improve the efficiency of industrial processes, leading to lower energy consumption and reduced operating costs.

- Extended Component Lifespan: Proper tribological design and maintenance can significantly extend the lifespan of machinery components, reducing the need for frequent repairs and replacements.

- Improved Reliability: Tribological failures can lead to unexpected equipment downtime, resulting in lost production and increased costs. By understanding and addressing tribological issues, companies can improve the reliability of their machinery and minimize downtime.

- Reduced Maintenance Costs: Effective tribological practices can help reduce maintenance costs by minimizing the need for frequent repairs and replacements.

- Enhanced Product Quality: Tribology plays a crucial role in determining the quality and performance of many industrial products. By optimizing tribological design and maintenance, companies can improve product quality and customer satisfaction.

In conclusion, tribology is a fundamental aspect of modern industry, with significant benefits in terms of efficiency, reliability, and cost-effectiveness. By understanding and applying tribological principles, companies can optimize the performance of their machinery, reduce environmental impact, and improve overall productivity.