Nanoindentation is a technique used to measure the mechanical properties of materials at the nanoscale. It involves pressing a sharp, diamond indenter into a material and measuring the resulting indentation. This method allows researchers to study the behavior of materials at extremely small scales, which is crucial in fields like materials science, nanotechnology, and engineering.

The Nanoindentation Process

- Indentation: A diamond indenter, typically a Berkovich or cube corner shape, is pressed into the material with a controlled force.

- Load-displacement curve: As the indenter penetrates the material, the load and displacement are recorded. This data is used to create a load-displacement curve.

- Hardness calculation: The hardness of the material is calculated from the load-displacement curve using various models, such as the Oliver-Pharr method.

Applications of Nanoindentation

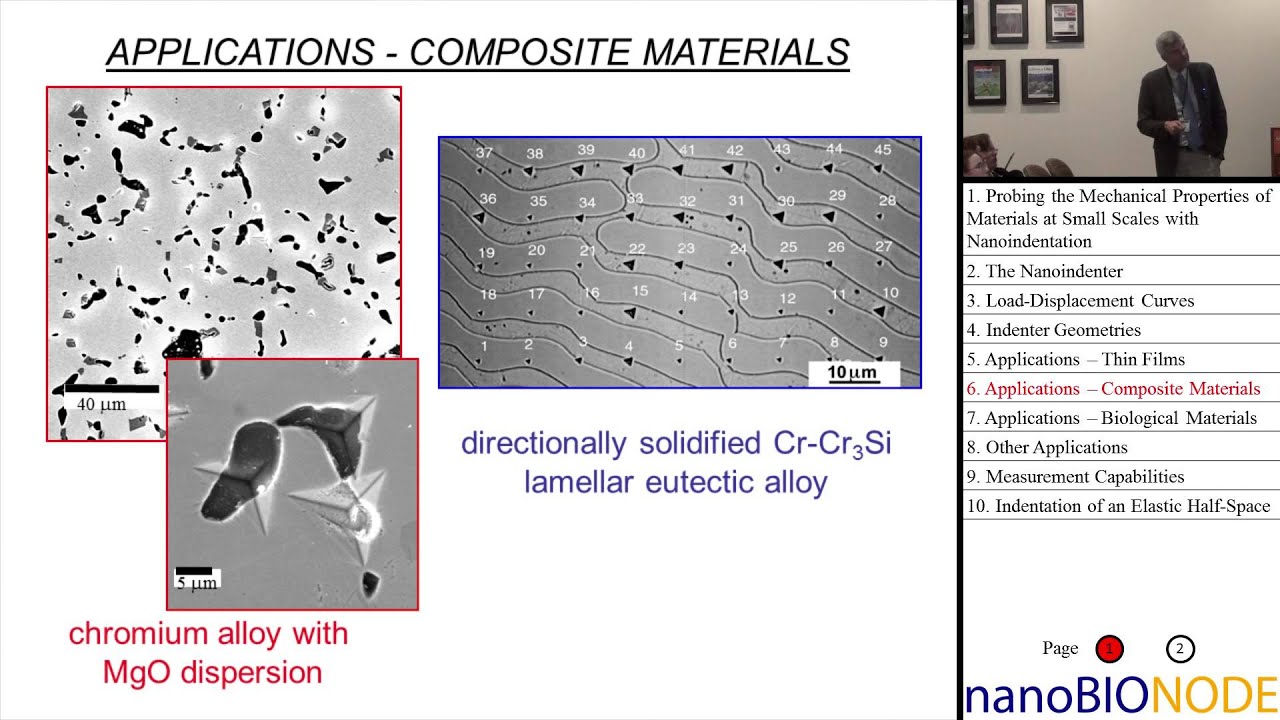

- Materials science: Characterizing the mechanical properties of materials like metals, ceramics, polymers, and composites at the nanoscale.

- Nanotechnology: Studying the properties of nanomaterials, such as nanotubes and nanoparticles.

- Thin film analysis: Evaluating the mechanical properties of thin films and coatings.

- Failure analysis: Investigating the causes of material failures at the nanoscale.

- Biomaterials: Studying the mechanical properties of biological materials, such as bone and cartilage.

Advantages of Nanoindentation

- High sensitivity: Can measure the mechanical properties of materials at extremely small scales.

- Non-destructive: Can be performed without damaging the material.

- Versatility: Can be used on a wide range of materials.

- Quantitative analysis: Provides quantitative data on hardness, modulus, and other mechanical properties.

Challenges of Nanoindentation

- Instrument sensitivity: Requires highly sensitive instruments to measure the small forces and displacements involved.

- Data analysis: Analyzing nanoindentation data can be complex, requiring specialized software and expertise.

- Sample preparation: Preparing samples for nanoindentation can be challenging, especially for soft or delicate materials.

Nanoindentation has become an indispensable tool for researchers and engineers working at the nanoscale. By providing insights into the mechanical properties of materials, it is helping to advance our understanding of materials science and drive innovation in various fields.