Aerospace tribology is the study of friction and wear in aerospace components. It is a critical field that plays a vital role in ensuring the safety, reliability, and efficiency of aircraft and spacecraft.

Key Areas of Aerospace Tribology

- Engine Tribology: This involves the study of friction and wear in engine components, such as turbine blades, bearings, and seals. Reducing friction in these components can improve engine efficiency, reduce fuel consumption, and enhance durability.

- Landing Gear Tribology: This focuses on the friction and wear behavior of landing gear components, including tires, brakes, and shock absorbers. Ensuring proper tribological performance is essential for safe and reliable landing operations.

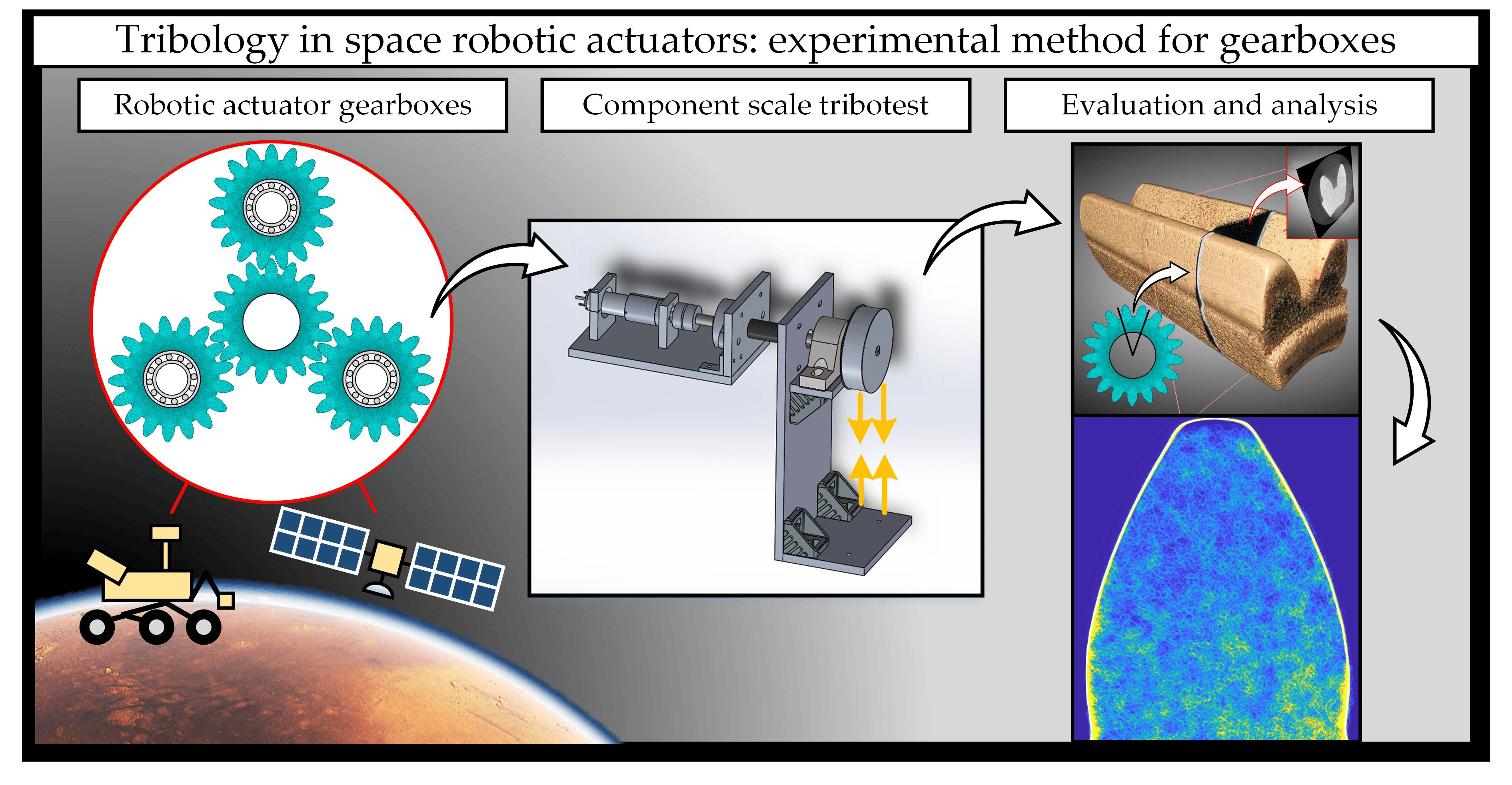

- Spacecraft Tribology: This involves the study of friction and wear in spacecraft components, such as solar panels, joints, and mechanisms. Reducing friction is crucial for minimizing wear and ensuring the longevity of spacecraft in harsh environments.

Challenges and Opportunities in Aerospace Tribology

- Extreme Conditions: Aerospace components operate in harsh environments, including high temperatures, low pressures, and exposure to corrosive substances. This poses significant challenges for tribological performance.

- Lightweight Materials: The increasing use of lightweight materials in aerospace applications, such as composites and alloys, requires careful consideration of their tribological properties.

- Reliability and Safety: Ensuring the reliability and safety of aerospace components is paramount. Tribology plays a crucial role in preventing failures due to friction and wear.

- Sustainability: Reducing friction and wear in aerospace components can contribute to improved fuel efficiency and reduced environmental impact.

Advancements in Aerospace Tribology

- Advanced Materials: The development of new materials with improved tribological properties, such as nanomaterials and superalloys, is a key area of research.

- Lubricants: The development of advanced lubricants that can withstand extreme conditions and provide effective friction reduction is another important focus.

- Surface Coatings: Applying specialized coatings to components can help to reduce friction, wear, and corrosion.

- Simulation and Modeling: Computer simulations and modeling are used to study friction and wear behavior in aerospace components, allowing for optimization and testing before physical prototypes are built.

Aerospace tribology is a dynamic field with significant potential to improve the performance, reliability, and sustainability of aircraft and spacecraft. By addressing the challenges and capitalizing on the opportunities, researchers and engineers can continue to advance the science of friction and wear in the aerospace industry.