Industrial machinery refers to the equipment and tools used in manufacturing, production, and processing industries. It encompasses a wide range of machines, from simple hand tools to complex automated systems.

Types of Industrial Machinery

- Material Handling Equipment: Used to move, lift, and transport materials within a factory or warehouse. Examples include forklifts, cranes, conveyors, and robots.

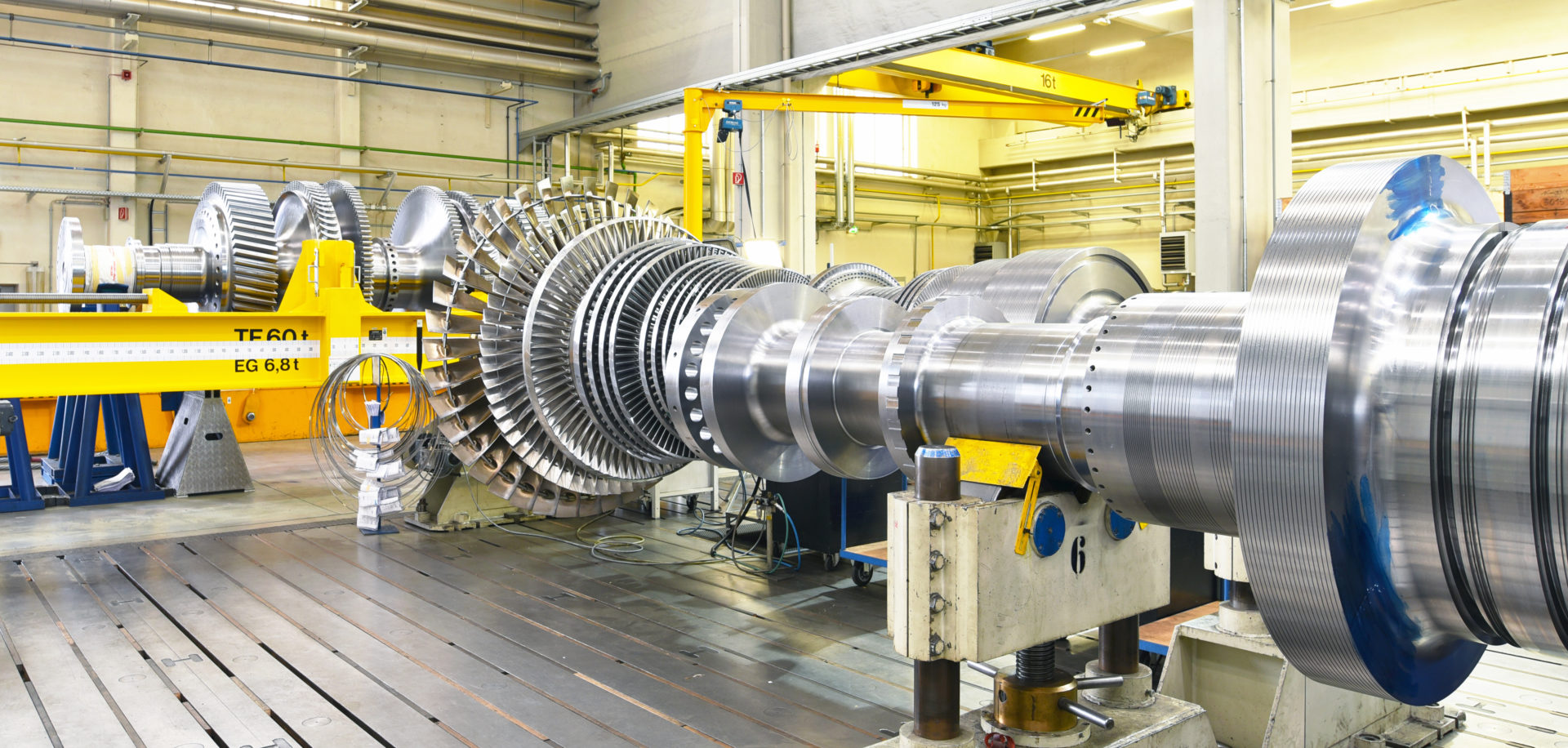

- Processing Machinery: Used to transform raw materials into finished products. Examples include lathes, milling machines, drilling machines, and presses.

- Assembly Machinery: Used to assemble components into finished products. Examples include robotic arms, assembly lines, and automated welding machines.

- Packaging Machinery: Used to package products for distribution. Examples include filling machines, sealing machines, and labeling machines.

- Testing and Inspection Machinery: Used to test and inspect products for quality and compliance. Examples include quality control machines, inspection cameras, and testing equipment.

Benefits of Industrial Machinery

- Increased Efficiency: Industrial machinery can significantly improve production efficiency by automating tasks and reducing manual labor.

- Improved Quality: Modern machinery is often equipped with advanced controls and sensors that can help to ensure product quality and consistency.

- Cost Reduction: By automating processes and reducing waste, industrial machinery can help to lower production costs.

- Safety: Industrial machinery can help to improve workplace safety by reducing the risk of accidents and injuries.

- Innovation: Advancements in industrial machinery technology are driving innovation and enabling new manufacturing processes.

Trends in Industrial Machinery

- Automation: The increasing adoption of automation technologies, such as robotics and artificial intelligence, is transforming the way industrial machinery is used.

- Digitalization: The integration of digital technologies, such as the Internet of Things (IoT) and Industry 4.0, is enabling greater connectivity and data-driven decision-making in industrial machinery.

- Sustainability: There is a growing focus on developing industrial machinery that is more energy-efficient and environmentally friendly.

- Customization: The ability to customize industrial machinery to meet specific needs is becoming increasingly important.

Industrial machinery plays a vital role in driving economic growth and supporting various industries. As technology continues to advance, we can expect to see even more innovative and efficient industrial machinery solutions in the future.