Microhardness testing is a technique used to determine the hardness of very small materials or thin coatings. It is particularly useful for materials that cannot be tested using conventional hardness testing methods due to their size or fragility.

Microhardness Testing Methods

There are two primary methods of microhardness testing:

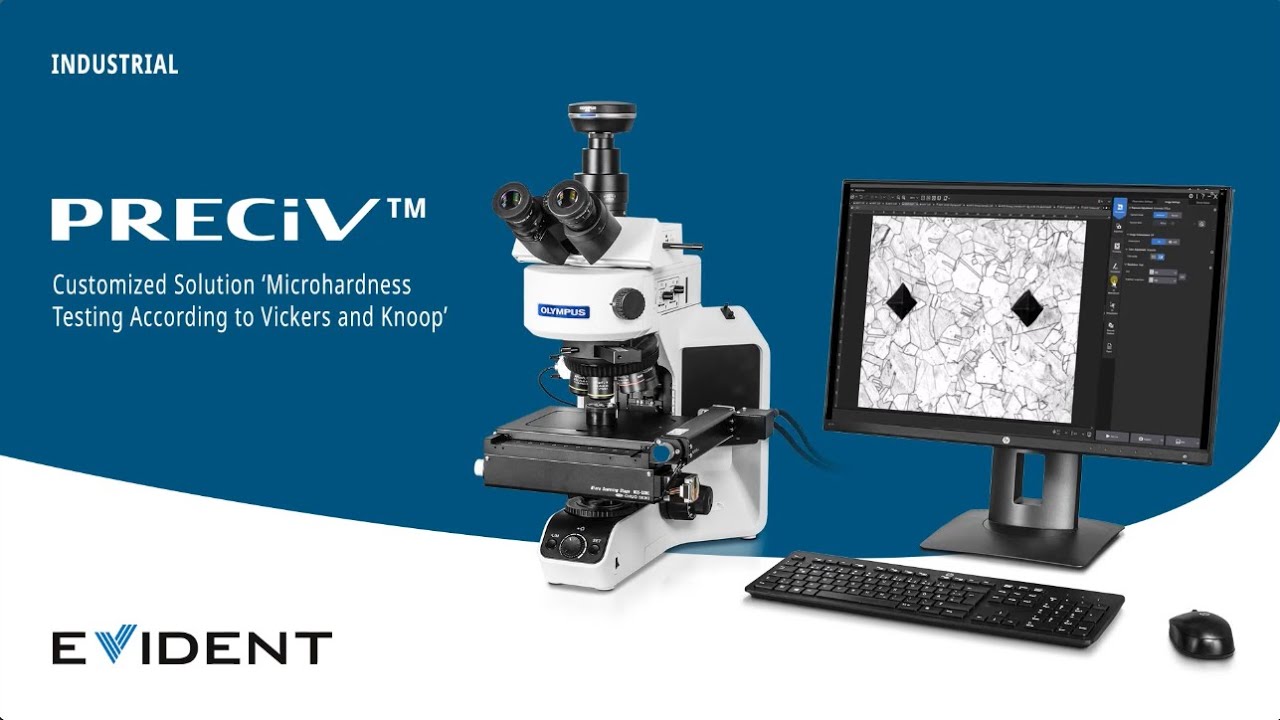

- Knoop hardness test: This method uses a diamond pyramid indenter with a specific shape and size. The indenter is pressed into the material with a known force, and the resulting indentation is measured. The Knoop hardness number (KHN) is calculated based on the indentation size and the applied force.

- Vickers hardness test: This method uses a square diamond pyramid indenter. The procedure is similar to the Knoop hardness test, and the resulting Vickers hardness number (VHN) is calculated based on the indentation size and applied force.

Advantages of Microhardness Testing

- High sensitivity: Microhardness testing can measure the hardness of very small materials and thin coatings.

- Non-destructive: In many cases, microhardness testing can be performed without damaging the material.

- Versatility: Microhardness testing can be used on a wide range of materials, including metals, ceramics, polymers, and composites.

Applications of Microhardness Testing

Microhardness testing is used in various industries, including:

- Materials science: Evaluating the properties of new materials and coatings.

- Manufacturing: Assessing the quality of finished products.

- Failure analysis: Investigating the causes of material failures.

- Research: Studying the relationship between hardness and other material properties.

Factors Affecting Microhardness

Several factors can influence the microhardness of a material, including:

- Material properties: The composition, microstructure, and heat treatment of the material.

- Indentation load: The force applied to the indenter.

- Indentation time: The duration of the indentation.

- Surface preparation: The surface finish of the material.

By understanding the factors that affect microhardness and conducting appropriate testing, engineers and scientists can evaluate the properties of materials and ensure their suitability for specific applications.