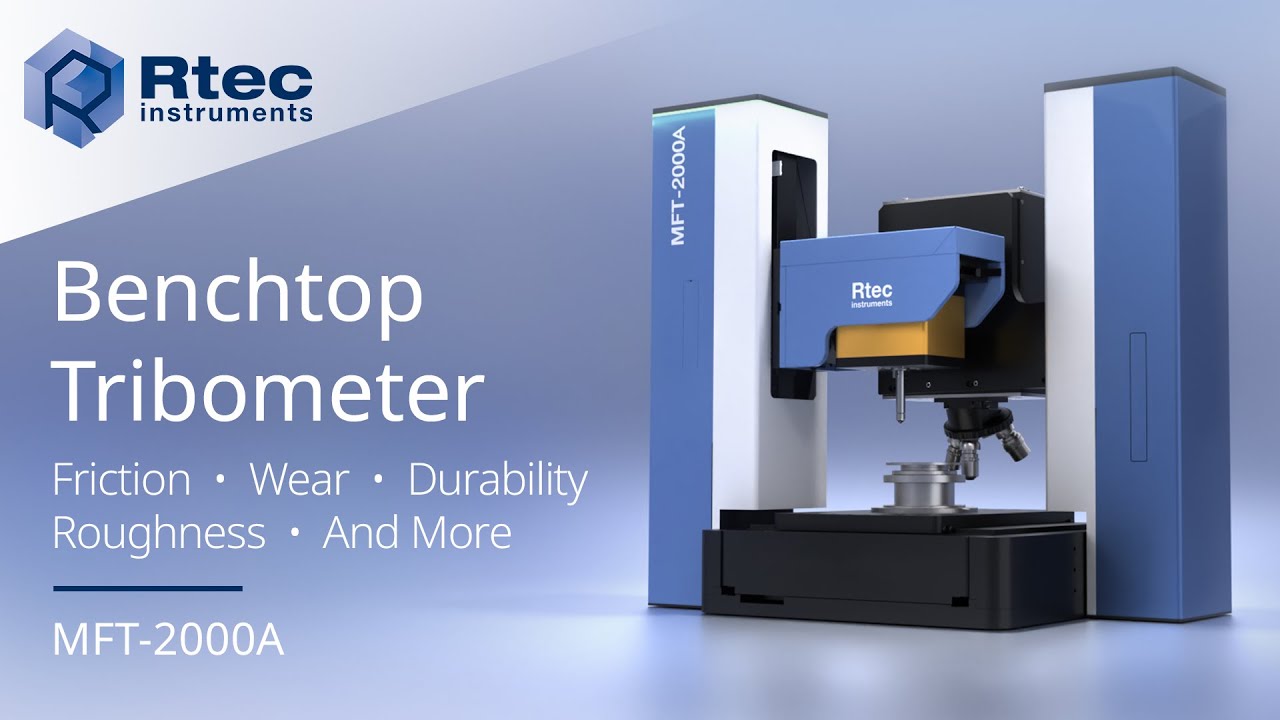

A tribometer is a scientific instrument used to measure friction and wear between two surfaces. It is an essential tool in various industries, including materials science, engineering, and manufacturing, as it helps researchers and engineers understand the behavior of materials under different conditions.

Components of a Tribometer

A typical tribometer consists of the following components:

- Load application system: This component applies a controlled force between the two surfaces being tested.

- Motion control system: This system controls the relative motion between the surfaces, such as sliding, rolling, or reciprocating motion.

- Friction measurement system: This component measures the force required to overcome friction between the surfaces.

- Wear measurement system: This system measures the amount of material lost from the surfaces due to wear.

Types of Tribometers

There are several types of tribometers, each designed for specific applications:

- Pin-on-disc tribometer: This type consists of a pin-shaped specimen that is pressed against a rotating disc. It is commonly used for testing the wear resistance of coatings and surface treatments.

- Ball-on-disc tribometer: Similar to the pin-on-disc tribometer, but uses a ball-shaped specimen instead of a pin.

- Block-on-ring tribometer: This type uses a block-shaped specimen that slides against a rotating ring. It is often used for testing the friction and wear behavior of bulk materials.

- Reciprocating tribometer: This type simulates sliding motion back and forth. It is useful for testing the wear behavior of materials under cyclic loading conditions.

Applications of Tribometers

Tribometers are used in a wide range of applications, including:

- Materials testing: Evaluating the wear resistance, friction coefficient, and other properties of materials.

- Lubricant testing: Assessing the effectiveness of lubricants in reducing friction and wear.

- Surface coating evaluation: Testing the performance of surface coatings and treatments.

- Component design: Optimizing the design of mechanical components to improve their durability and efficiency.

- Failure analysis: Investigating the causes of mechanical failures.

By providing accurate measurements of friction and wear, tribometers play a crucial role in advancing our understanding of materials behavior and improving the design and performance of mechanical systems.